EV range fears could be a thing of the past thanks to Mercedes’ new solar paint, which promises thousands of free miles per year

- Mercedes has unveiled a range of future innovations during workshops

- The ‘solar paint’ contains no rare earth metals and no toxic substances

- Aerodynamic braking and power converters aim to improve EV efficiency

What is solar paint?

Mercedes says the new type of solar paint can be used on “all exterior surfaces of vehicles.” It also claims that typical solar panels are “significantly cheaper” to produce and are easy to recycle, thanks to the lack of rare earth elements and silicon.

The utopian dream of solar-powered driving may not seem so far away, as Mercedes-Benz recently opened the doors to some of its most progressive engineering labs – and it turns out photovoltaic surfaces are high on the agenda.

During a series of workshops in its home city of Stuttgart, Germany, Mercedes-Benz explained how it has been working on a new kind of solar surface that could generate enough electricity for people in sunnier climates to power their daily commute.

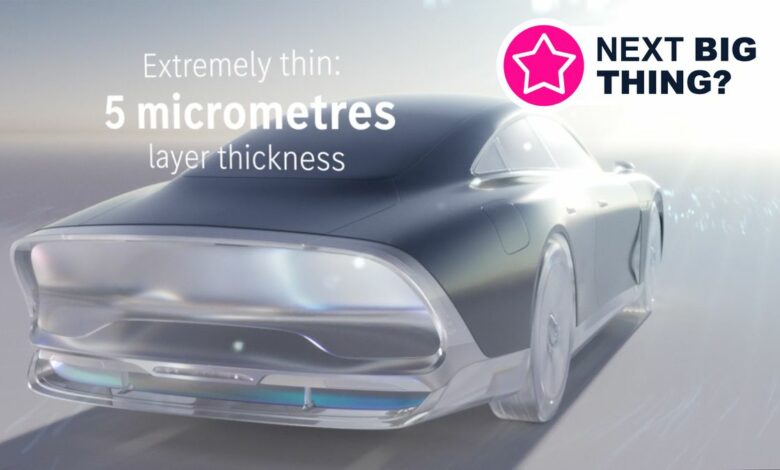

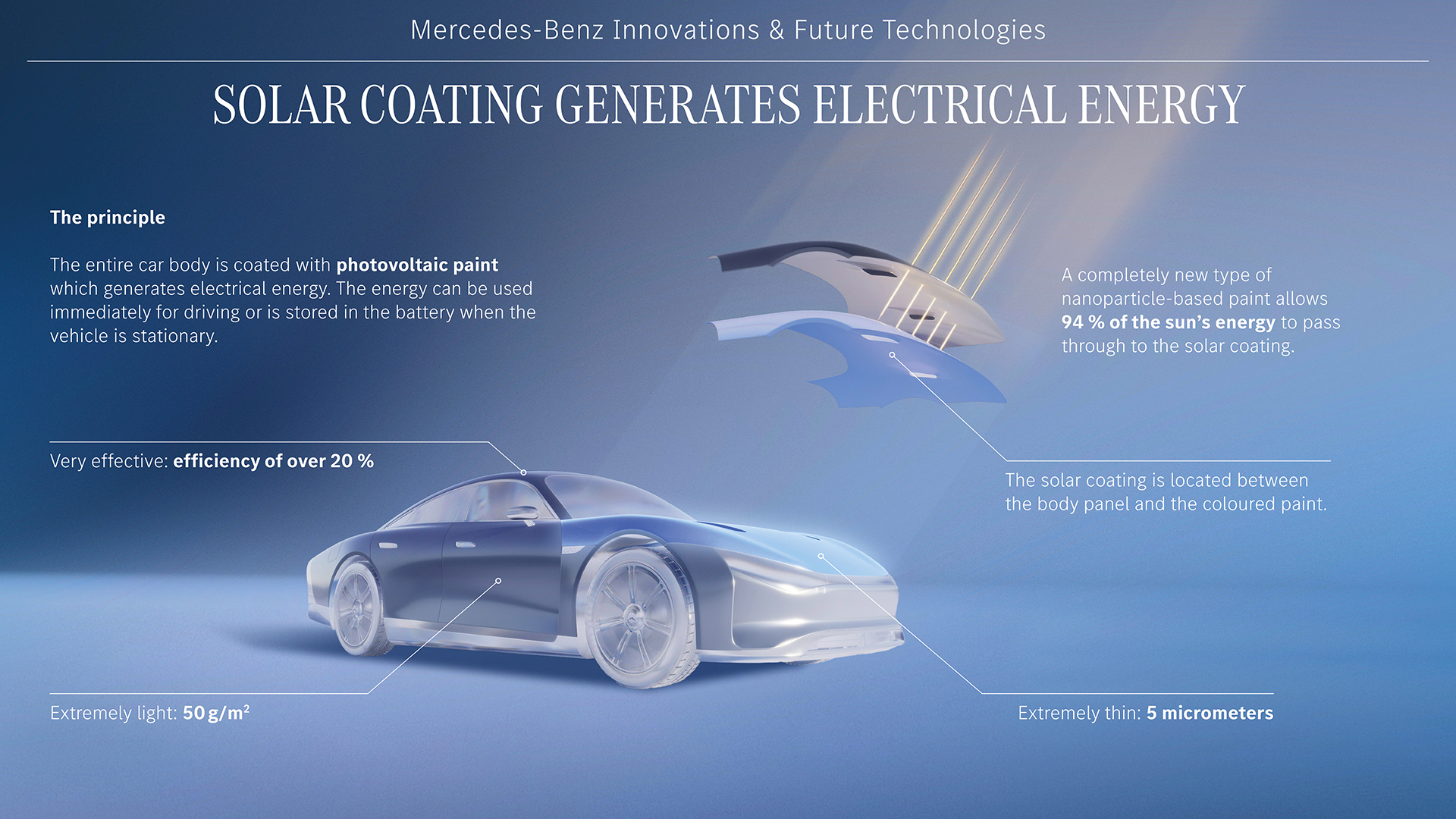

According to the German brand, the ‘solar panels’ are only five micrometers thick – significantly thinner than a human hair – and weigh just 50 grams per square meter. They can be applied to virtually any substrate, with future vehicle applications likely to come in the form of a “wafer-thin layer of paste” that will cover most of the bodywork.

Mercedes-Benz has previous experience with solar panels and the impact they can have on the electric range of electric vehicles, as the company’s record-breaking EQXX concept (the rolling laboratory that traveled more than 1,000 kilometers on a single charge) used a small solar panel on the roof, which added about 20 miles (30 km) of extra range during one of its long-distance record attempts.

But the breakthrough in photovoltaic surface treatments means a much larger part of a vehicle can be covered, meaning a much larger increase in additional EV mileage.

No need for gigantic solar panels

Taking a fairly standard mid-size SUV like the brand’s EQS as an example, Mercedes engineers claim that the 11 square meters of surface area and the technology’s 20% solar energy efficiency would be enough to power around 12,000 kilometers of motoring per year in a sunny spot. , such as Los Angeles.

Nanoparticle-based paint is also said to allow 94% of the sun’s energy to pass through to the solar coating, meaning future electric vehicles won’t necessarily have to look like giant solar panels.

When studying the daily driving habits of EV owners in Stuttgart, Germany, those close to the project found that they travel an average of 52 kilometers (about 32 miles) per day. About 62% of this distance could be covered using solar energy, the company says, despite often poor weather conditions.

Again, if you live somewhere with plenty of sunshine, the ‘always on’ nature of a photovoltaic surface means the vehicle can be charged effectively even when parked.

As a result, LA owners were able to cover an average of 100% of their driving distance with solar power. Any excess could, in theory, be delivered directly to the home network via bi-directional charging.

Stopping inefficiencies

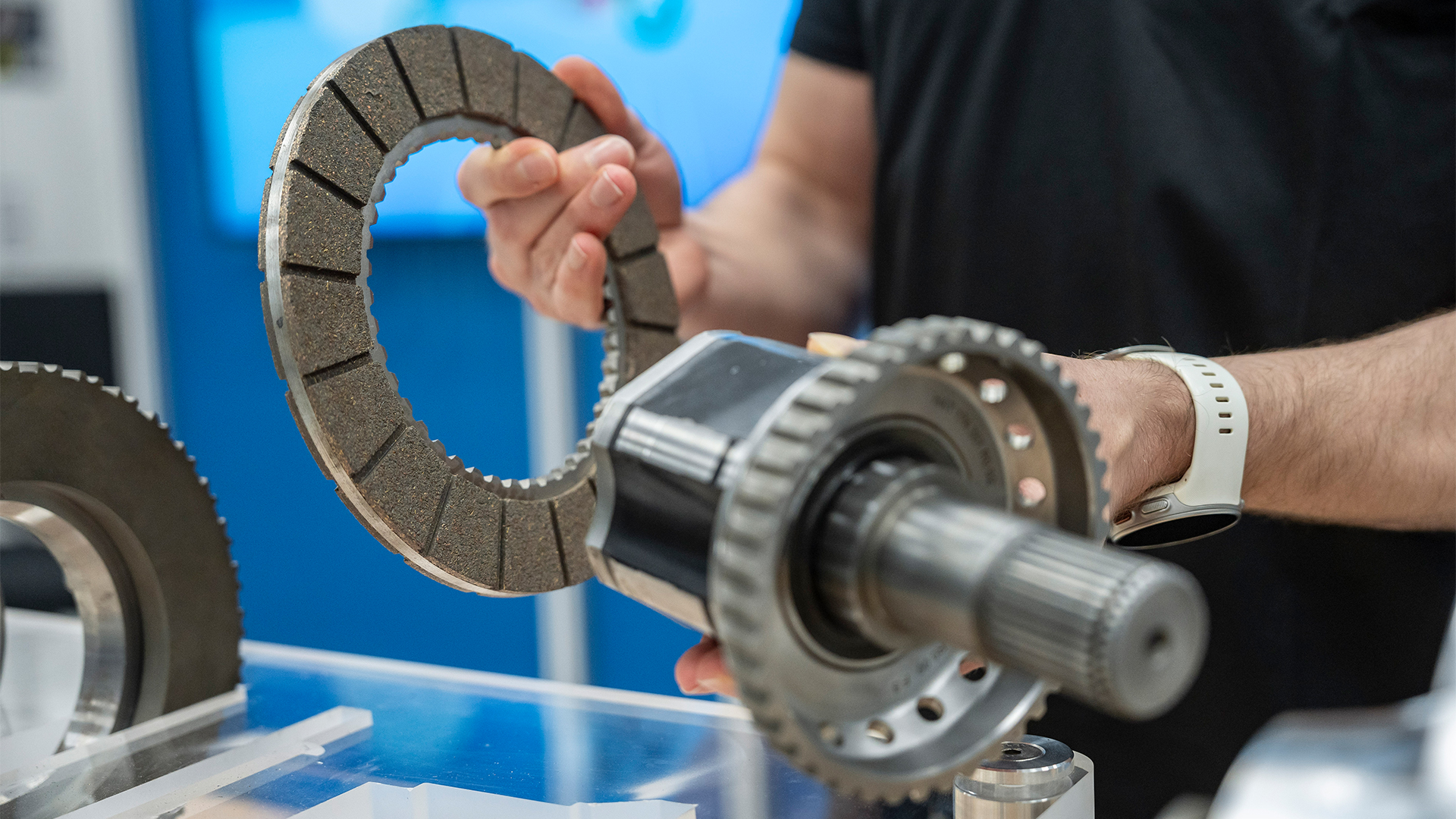

In addition to thinking about the state of future cities and accelerating AI decisions with neuromorphic computing, Mercedes-Benz also pointed out that it is also working on an EV braking system that eliminates the need for standard discs, drums and brake pads.

To effectively rid the world of harmful particles emitted in the form of brake dust, Mercedes’ innovation is integrated into the electric drive unit on the front or rear axle, eliminating the need for brakes in the wheels.

Not only would this be subject to minimal wear and take up less space, it would also mean the company could look at much lighter wheel and tire combinations, reducing the overall mass of an electric car, and towards fully enclosed rims for optimized aerodynamics. , because openings for brake cooling would no longer be necessary.

Additionally, the company’s research into electrical inverter systems could include the integration of micro-converters directly at the battery cell level, which would allow greater control over individual cells.

It’s complicated stuff, but it would result in more efficient battery performance, longer battery pack life and greater freedom when it comes to packaging – allowing engineers to use different cell designs throughout the vehicle.

All these developments are still a long way from reaching production, but it’s good to see that Mercedes-Benz is exploring innovations that offer real value to its future customers.